-

+(91) - 812 31113000

-

+ (91) - 9449824141 / + (91) - 7760294141

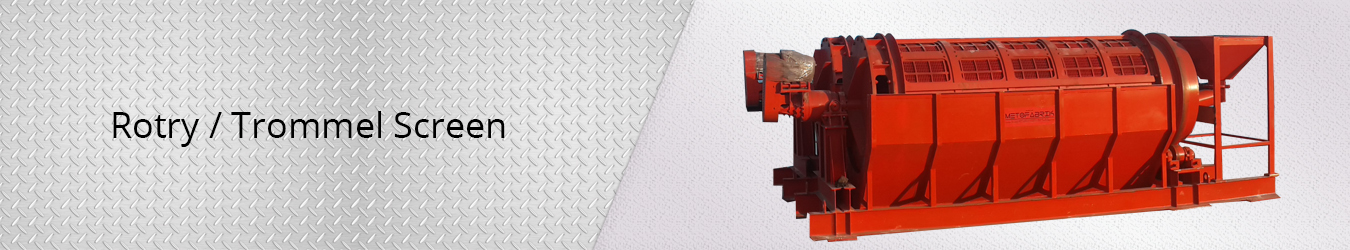

Rotry / Trommel Screen

- Salient Features of Vibrating Grizzly Feeders

- Custom designed & built

- Energy efficient

- Inline planetary reducer drive

- State of the art submerged bearing assembly

- Powerful hydraulic spiral lifting device

- Wide range of application

- Easy to maintain & operate

- Rigid substructure design

- Optional anti corrosion treatment for tank

- Over flow collection launder

- Adjustable weirs

- Continuous raking

Regardless of application, there are three basic steps used in the sizing of a spiral classifier. These are determination of settling rate, determination of required overflow rate, and determination of raking or underflow capacity. All the technical feed back is first collected from the client and then each of these basic sizing elements are reviewed and then a Spiral Classifier is made which dimensionally satisfies the sizing parameters.

The key component of a spiral classifier is the main shaft, which is carefully designed and selected to prevent deflection due to the spiral weight and the thrust load imposed by the spiral during raking. Large diameter, seamless steel, tubular shaft with sufficient wall thickness are used for minimum deflection. Heavy duty cast steel arms are clamped to the main shaft. The Spiral Classifier consists of sectional circular steel flights bolted to the arms to form a continuous spiral. Replaceable abrasion resistant wear shoes are fastened to the lead edge of the flights. Shoe material is available in chrome iron, Ni-hard or polyurethane as options.

The lower submerged bearing assembly is again one the most important component of the spiral classifier responsible for its smooth and efficient working for a very long time. Metofabrik has designed and developed its state of the art submerged bearing assembly. The assembly consists of heavy duty housing fitted with roller bearings and multiple sets of seals to keep the roller bearing away from contamination. The submerged bearing assembly can be lubricated in operation / running, from a grease pipe extending from the submerged assembly to a grease fitting at the upper end.

An efficient hydraulic arrangement is made for easy lifting and lowering of the spiral before starting or during operations. This lifting arrangement is also very convenient for periodic inspections of the spiral and preventive maintenance.

The Metofabrik Spiral Classifiers are driven by flange mounted in-line planetary geared motor or reducer via "V" belt and an electric motor. Optional V. F. D. can also be supplied. The reducer is flanged mounted on the pivoted upper bearing assembly along with an electric motor which swivels in tandem with the spiral assembly when the main shaft is raised or lowered.

CONTACT US

- Address : 214, Jadhav Compound, Udyambag

Belgaum - 590 008. - Mobile :+(91) - 94498 24141

- Tele Fax : +(91) - 812 31113000 Email : info@metofabrik.in

Copyright © 2018 By Metofabrik. All Rights Reserved.